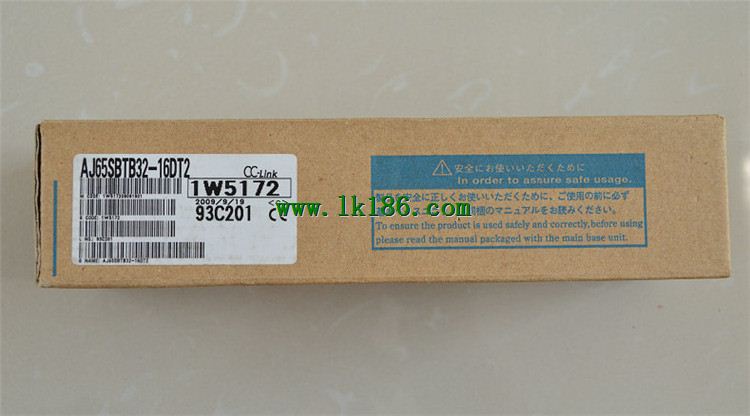

AJ65SBTB32-16DT2 Output form: transistor output, leakage type MITSUBISHI AJ65SBTB32-16DT2 DC input / transistor output module

Input and output points: 2048 points.

Input / output data points: 2048 points.

Program capacity: 30K.

Basic command processing speed (LD command) s:1.0.

Optical data communication line function (GI cable).

Each scanning process. Focus on the input signal sampling. Focus on the output signal to refresh AJ65SBTB32-16DT2.

Input refresh process. When the input port is closed,

Program in the implementation phase, the input end of a new state, the new state can not be read.

Only when the program is scanned, the new state is read AJ65SBTB32-16DT2.

A scan cycle is divided into the input sample, the program execution, the output refresh.

The contents of the component image register are changed with the change of the execution of the program.

The length of the scan cycle is determined by the three AJ65SBTB32-16DT2.

CPU the speed of executing instructions.

Time of instruction.

Instruction count.

Due to the adoption of centralized sampling.

Centralized output mode.

There exist input / output hysteresis phenomena, i.e., the input / output response delay.

User program storage capacity: it is a measure of how much the user application can store the number of indicators MITSUBISHI AJ65SBTB32-16DT2.

Usually in words or K words as units. 16 bit binary number is a word,

Every 1024 words are 1K words. PLC to store instructions and data in words.

General logical operation instructions each account for 1 words MITSUBISHI AJ65SBTB32-16DT2. Timer / counter,

Shift instruction accounted for 2 words. Data operation instructions for 2~4. Type of input: DC source.

Input points: 32 points.

Input voltage: DC12/24.

Input current: 3/7mA.

Connection mode: terminal row.

Common common point: 32 MITSUBISHI AJ65SBTB32-16DT2.

Sequential function flow chart language is designed to satisfy the sequential logic control.

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions.

Each step represents a control function, represented by the box.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time.

Used in the system of the size of the school, procedures for more complex occasions.

Sequence function flow chart programming language features: to function as the main line, in accordance with the functional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the complicated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced.

Input type: DC input, positive common end.

Input points: 8 points.

Enter the response time: 1.5ms the following.

Rated input voltage / current: DC24V/7mA.

Output form: transistor output, leakage type.

Output points: 8 points.

OFF leakage current: 0.1mA.

Output protection function: No.

Rated load voltage / current: DC24V/0.5A.

External connection: 3 line /2 line type.

According to the external connection mode and the external equipment input and output specifications,

Choose from a rich product lineup AJ65SBTB32-16DT2.

Finger protection through the upper part of the terminal,

The human body will not be exposed to live parts,

Therefore, the terminal station type remote I/O module can be directly mounted to the machine tool.